Form: :

2024-01-31 04:50:06

0

Toggle switches are widely used in various industries and applications, from electronics and telecommunications to automotive and industrial equipment. These switches provide a simple and reliable way to control the flow of electricity, making them an essential component in many devices and systems. To ensure that toggle switches are used effectively and safely, it is crucial to provide comprehensive product training. In this article, we will explore the key considerations for toggle switch product training, including the importance of understanding switch types, applications, and safety guidelines.Understanding Switch Types

Toggle switches come in different types, each designed for specific applications and environments. It is essential for product training to cover the various switch types and their characteristics to ensure that users can select the right switch for their needs. Some common toggle switch types include:1. Single-Pole Single-Throw (SPST): This is the simplest type of toggle switch, with two terminals that are either connected or disconnected when the switch is toggled.2. Single-Pole Double-Throw (SPDT): This switch has three terminals, allowing the user to connect one terminal to either of the other two terminals.3. Double-Pole Single-Throw (DPST): With four terminals, this switch can control two separate circuits simultaneously.4. Double-Pole Double-Throw (DPDT): Similar to DPST, this switch has six terminals and can control two circuits independently.Product training should provide detailed explanations and visual aids to help users understand the differences between these switch types and their applications. This knowledge will enable users to make informed decisions when selecting toggle switches for their specific requirements.Applications and Use Cases

Toggle switches are used in a wide range of applications, and product training should cover these applications to help users understand the versatility of toggle switches. Some common applications include:1. Electronics: Toggle switches are commonly used in electronic devices, such as computers, audio equipment, and control panels. Product training should explain how toggle switches are integrated into these devices and how they contribute to their functionality.2. Automotive: Toggle switches are widely used in automotive applications, including controlling lights, wipers, and other electrical systems. Training should cover the specific requirements and safety considerations for toggle switches in automotive environments.3. Industrial Equipment: Toggle switches are essential in industrial equipment, such as machinery, control panels, and power distribution systems. Training should focus on the robustness and reliability of toggle switches in demanding industrial environments.4. Telecommunications: Toggle switches are used in telecommunications equipment, such as routers, switches, and communication devices. Training should explain how toggle switches enable the smooth operation of these systems and the importance of proper switch selection.By providing comprehensive training on the various applications and use cases of toggle switches, users will gain a deeper understanding of how these switches contribute to the functionality and performance of different devices and systems.Safety Guidelines

Toggle switches, like any electrical component, require adherence to safety guidelines to prevent accidents and ensure user safety. Product training should emphasize the importance of following safety guidelines when working with toggle switches. Some key safety considerations include:1. Electrical Safety: Users should be trained on basic electrical safety practices, such as turning off the power source before working on electrical circuits and using appropriate personal protective equipment (PPE) when handling toggle switches.2. Proper Installation: Training should cover the correct installation procedures for toggle switches, including proper wiring techniques, secure mounting, and ensuring proper grounding.3. Environmental Considerations: Toggle switches may be exposed to various environmental conditions, such as moisture, dust, and extreme temperatures. Training should highlight the importance of selecting switches with appropriate environmental ratings and taking necessary precautions to protect switches from adverse conditions.4. Maintenance and Inspection: Regular maintenance and inspection of toggle switches are crucial to ensure their continued functionality and safety. Training should provide guidelines on how to inspect switches for signs of wear, damage, or loose connections and how to perform routine maintenance tasks.By incorporating safety guidelines into toggle switch product training, users will be equipped with the knowledge and skills to handle toggle switches safely, reducing the risk of accidents and ensuring the longevity of the switches.Conclusion

Toggle switches are essential components in various industries and applications, and providing comprehensive product training is crucial to ensure their effective and safe use. By covering switch types, applications, and safety guidelines, users will gain a deeper understanding of toggle switches and be able to select, install, and maintain them properly. With proper product training, users can maximize the functionality and reliability of toggle switches, contributing to the overall performance of their devices and systems.

Form: :

2024-01-31 03:16:17

0

Title: The Mainstream Rotary Switch Production Process: A Comprehensive OverviewIntroduction (100 words)

Rotary switches are widely used in various industries, including electronics, telecommunications, and automation. These switches provide a reliable and efficient means of controlling electrical circuits. Understanding the production process of rotary switches is crucial for manufacturers and consumers alike. In this article, we will delve into the mainstream rotary switch production process, exploring the key steps involved, the materials used, and the quality control measures implemented. By gaining insights into this process, we can appreciate the complexity and precision required to manufacture these essential components.1. Design and Engineering (200 words)

The production of rotary switches begins with the design and engineering phase. Manufacturers collaborate with engineers to develop a switch that meets the specific requirements of the intended application. This phase involves determining the switch's electrical specifications, mechanical dimensions, and desired features. Computer-aided design (CAD) software is employed to create detailed 2D and 3D models, allowing for precise visualization and evaluation of the switch design.2. Material Selection (150 words)

Once the design is finalized, the next step is selecting the appropriate materials for the rotary switch. The choice of materials depends on factors such as the switch's intended use, environmental conditions, and electrical requirements. Common materials used for rotary switches include brass, copper, stainless steel, and various types of plastics. These materials are selected for their durability, electrical conductivity, and resistance to corrosion.3. Manufacturing Processes (400 words)

The manufacturing of rotary switches involves several key processes, including metal stamping, plating, assembly, and testing.a. Metal Stamping: Metal stamping is a crucial step in rotary switch production. It involves using specialized machinery to cut, shape, and form metal components according to the switch design. Metal stamping ensures precise dimensions and consistent quality across a large volume of switches.b. Plating: Plating is performed to enhance the durability and conductivity of the switch components. The metal parts are coated with a thin layer of precious metals such as gold or silver, which provide excellent electrical contact and resistance to corrosion.c. Assembly: Once the metal components are stamped and plated, they are assembled into the final switch structure. This process involves carefully aligning and connecting the various parts, including the rotor, stator, contacts, and terminals. Adhesive bonding, soldering, or mechanical fastening techniques are employed to ensure secure connections.d. Testing: Quality control is a critical aspect of rotary switch production. Various tests are conducted to ensure the switches meet the required electrical and mechanical specifications. These tests include contact resistance measurement, insulation resistance testing, endurance testing, and environmental testing to assess the switch's performance under different conditions.4. Quality Control and Certification (200 words)

To ensure the reliability and safety of rotary switches, manufacturers implement stringent quality control measures. These measures involve inspecting and testing the switches at various stages of production. Additionally, manufacturers often obtain certifications such as ISO 9001, which demonstrate their commitment to quality management systems.5. Packaging and Distribution (150 words)

Once the rotary switches have passed the quality control tests, they are packaged and prepared for distribution. Packaging materials are carefully chosen to protect the switches during transportation and storage. Manufacturers may also include user manuals and relevant documentation to assist customers in understanding the switch's features and installation process. The switches are then distributed to wholesalers, retailers, or directly to end-users, depending on the manufacturer's distribution strategy.Conclusion (100 words)

The mainstream rotary switch production process involves a series of intricate steps, from design and engineering to manufacturing, testing, and distribution. Manufacturers must carefully select materials, employ advanced manufacturing techniques, and implement rigorous quality control measures to ensure the switches meet the required specifications. By understanding this process, consumers can appreciate the complexity and precision involved in producing these essential components that power countless electrical circuits across various industries.

Form: :

2024-01-31 01:04:07

0

Title: Exploring Popular Models of Rotary Switches: A Comprehensive GuideIntroduction (100 words)

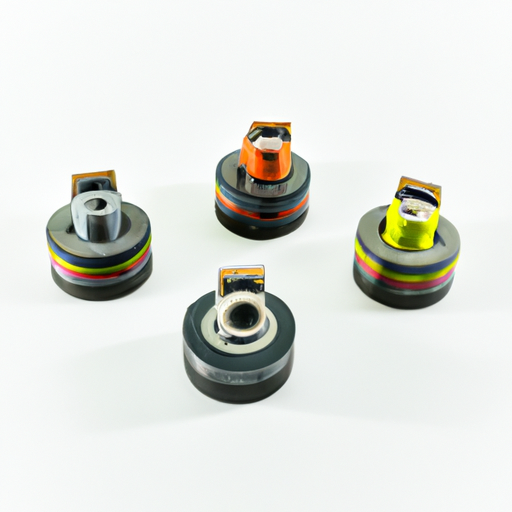

Rotary switches are widely used in various industries and applications due to their versatility and reliability. These switches offer multiple positions and can be easily rotated to select different functions or settings. In this article, we will explore some of the most common and popular models of rotary switches available in the market today. From basic single-pole, single-throw (SPST) switches to more complex multi-pole, multi-throw (MPMT) switches, we will delve into their features, applications, and advantages.1. Single-Pole, Single-Throw (SPST) Rotary Switches (200 words)

SPST rotary switches are the simplest and most common type of rotary switches. They consist of a single pole and a single throw, meaning they have only one input and one output. These switches are commonly used in applications where a simple on/off function is required, such as lamps, fans, and small appliances. The most popular models in this category include the C&K 7101 series and the Grayhill 71 series.2. Single-Pole, Double-Throw (SPDT) Rotary Switches (200 words)

SPDT rotary switches, also known as changeover switches, have a single input and two outputs. They allow the user to select between two different circuits or functions. These switches are commonly used in audio equipment, electronic instruments, and industrial control panels. The C&K 7103 series and the Grayhill 72 series are among the popular models in this category.3. Multi-Pole, Single-Throw (MPST) Rotary Switches (200 words)

MPST rotary switches have multiple poles but only one throw. They are commonly used in applications where multiple circuits need to be switched simultaneously. These switches are often found in industrial machinery, power distribution systems, and control panels. The C&K 7105 series and the Grayhill 74 series are well-known models in this category.4. Multi-Pole, Multi-Throw (MPMT) Rotary Switches (200 words)

MPMT rotary switches are the most complex and versatile type of rotary switches. They have multiple poles and multiple throws, allowing for a wide range of circuit configurations. These switches are commonly used in complex control systems, audio mixing consoles, and telecommunications equipment. The C&K 7107 series and the Grayhill 76 series are popular models in this category.5. Specialized Rotary Switches (200 words)

Apart from the basic types mentioned above, there are also specialized rotary switches designed for specific applications. These include rotary switches with built-in encoders for precise position sensing, rotary switches with detents for tactile feedback, and rotary switches with integrated LEDs for visual indication. The C&K 7109 series and the Grayhill 78 series are examples of specialized rotary switches.Conclusion (100 words)

Rotary switches are essential components in various industries and applications, providing reliable and efficient circuit switching capabilities. Understanding the different types and models of rotary switches available in the market is crucial for selecting the right switch for a specific application. From basic SPST switches to complex MPMT switches, each model offers unique features and advantages. By considering factors such as the number of poles and throws, as well as any specialized requirements, engineers and designers can make informed decisions when choosing rotary switches for their projects.

Form: :

2024-01-30 22:04:04

0

Title: Understanding the Mechanics of Power Switch ButtonsIntroduction (100 words)

Power switch buttons are ubiquitous in our daily lives, found on various electronic devices such as computers, smartphones, and household appliances. Despite their prevalence, many users are unaware of the intricate mechanics behind these seemingly simple buttons. In this article, we will delve into the inner workings of power switch buttons, exploring their different types, mechanisms, and the role they play in controlling the flow of electrical power.I. Types of Power Switch Buttons (200 words)

Power switch buttons come in various forms, each designed to suit different devices and user preferences. The most common types include toggle switches, push-button switches, rocker switches, and slide switches. Each type has its unique characteristics and mechanisms, determining how they function and interact with the device they control.II. Mechanical Components (300 words)

Power switch buttons consist of several mechanical components that work together to control the flow of electrical power. These components include the actuator, contacts, springs, and housing. The actuator is the part of the button that users interact with, while the contacts are responsible for completing or interrupting the electrical circuit. Springs provide the necessary tension to ensure proper operation, and the housing encloses and protects the internal components.III. Mechanisms of Operation (400 words)

The mechanisms behind power switch buttons can vary depending on the type and design. Toggle switches, for instance, use a lever-like actuator that moves between two positions, either completing or breaking the circuit. Push-button switches, on the other hand, rely on a momentary contact mechanism, where the button must be continuously pressed to maintain the circuit connection.Rocker switches combine the features of toggle and push-button switches, allowing users to press one side to turn on and the other side to turn off. Slide switches, as the name suggests, use a sliding mechanism to control the circuit connection. Understanding these mechanisms is crucial for users to operate power switch buttons effectively.IV. Safety Features (200 words)

Power switch buttons often incorporate safety features to prevent accidental activation or damage to the device. These features include key locks, protective covers, and illuminated indicators. Key locks require a specific key to operate the switch, reducing the risk of unauthorized use. Protective covers, such as flip covers or sliding panels, shield the button from accidental activation. Illuminated indicators, such as LED lights, provide visual feedback, indicating whether the device is powered on or off.V. Evolution and Future Developments (200 words)

Power switch buttons have evolved significantly over time, with advancements in technology and user interface design. The rise of touch-sensitive buttons and capacitive touchscreens has revolutionized the way we interact with electronic devices. These developments have led to more intuitive and aesthetically pleasing power switch buttons, enhancing user experience and device functionality.Conclusion (100 words)

Power switch buttons may appear simple on the surface, but their mechanics are far more complex. Understanding the different types, mechanisms, and safety features of power switch buttons is essential for users to operate their devices effectively and safely. As technology continues to advance, we can expect further innovations in power switch button design, making them even more user-friendly and seamlessly integrated into our daily lives.

Form: :

2024-01-18 01:57:04

0

Title: Common Power Switch Button Popular Models: A Comprehensive GuideIntroduction (100 words)

Power switch buttons are an essential component of various electronic devices, allowing users to turn them on or off with ease. In this article, we will explore some of the most popular power switch button models available in the market today. From traditional toggle switches to modern touch-sensitive buttons, we will discuss their features, applications, and advantages. Whether you are a tech enthusiast or a professional in the electronics industry, this comprehensive guide will help you understand the different types of power switch buttons and make informed decisions when choosing the right one for your needs.1. Traditional Toggle Switches (200 words)

Traditional toggle switches have been widely used for decades due to their simplicity and reliability. These switches consist of a lever that can be flipped up or down to turn the device on or off. They are commonly found in appliances, industrial equipment, and automotive applications. Toggle switches are available in various sizes, shapes, and configurations, including single-pole single-throw (SPST), single-pole double-throw (SPDT), and double-pole double-throw (DPDT). Their robust construction and ease of use make them a popular choice for many applications.2. Push Button Switches (200 words)

Push button switches are another common type of power switch button. They are designed to be pressed down to activate or deactivate the device. These switches are often used in consumer electronics, such as computers, gaming consoles, and home appliances. Push button switches can be momentary or latching, meaning they can either stay on as long as they are pressed or lock into position until pressed again. They are available in various colors, shapes, and sizes, allowing for customization and easy integration into different devices.3. Rocker Switches (200 words)

Rocker switches are characterized by their distinctive rocking motion. They have a lever that can be moved back and forth to turn the device on or off. Rocker switches are commonly found in household appliances, automotive applications, and industrial equipment. They are available in different configurations, including SPST, SPDT, and DPDT. The large surface area of rocker switches makes them easy to operate, even with gloved hands. Additionally, some models feature illuminated indicators, allowing users to easily identify the switch's status in low-light conditions.4. Slide Switches (200 words)

Slide switches are compact and easy to use, making them suitable for small electronic devices. They consist of a lever that slides horizontally to turn the device on or off. Slide switches are commonly used in mobile phones, audio equipment, and handheld gaming consoles. They are available in various configurations, including SPST and DPDT. Slide switches are known for their space-saving design and durability, making them ideal for applications where size and reliability are crucial.5. Touch-Sensitive Buttons (200 words)

Touch-sensitive buttons, also known as capacitive touch switches, have gained popularity in recent years due to their sleek design and user-friendly interface. These buttons do not require physical pressure to activate; instead, they respond to the touch of a finger or a conductive object. Touch-sensitive buttons are commonly found in smartphones, tablets, and home automation systems. They offer a modern and intuitive user experience, often featuring customizable backlighting and haptic feedback. However, they may require additional circuitry and are more susceptible to false triggering caused by moisture or dirt.Conclusion (100 words)

Power switch buttons come in various models, each with its own unique features and advantages. From traditional toggle switches to modern touch-sensitive buttons, the choice depends on the specific requirements of the device and the user's preferences. Understanding the different types of power switch buttons discussed in this article will help individuals make informed decisions when selecting the most suitable model for their applications. Whether it's for household appliances, automotive equipment, or consumer electronics, the right power switch button can enhance the user experience and ensure reliable operation.

Form: :

2024-01-17 23:25:05

1

Title: The Mainstream DIP Switch Production Process: A Comprehensive OverviewIntroduction (100 words)

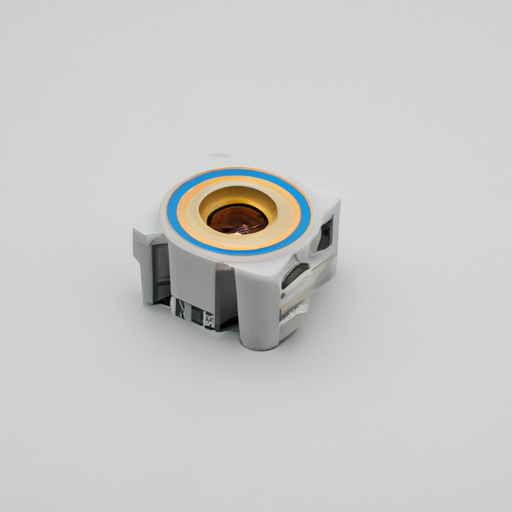

The production process of DIP (Dual Inline Package) switches, a widely used electronic component, involves several intricate steps. This article aims to provide a comprehensive overview of the mainstream DIP switch production process. From the initial design and material selection to the final testing and packaging, each stage plays a crucial role in ensuring the quality and functionality of these switches. By understanding the intricacies of DIP switch production, manufacturers can optimize their processes and deliver reliable products to meet the ever-growing demands of the electronics industry.1. Design and Development (200 words)

The production process of DIP switches begins with the design and development phase. Manufacturers collaborate with engineers and designers to create a product that meets the specific requirements of the target market. This involves determining the switch's electrical specifications, physical dimensions, and mechanical features. Computer-aided design (CAD) software is often employed to create detailed 2D and 3D models, allowing for precise visualization and modification of the switch design.2. Material Selection (200 words)

Once the design is finalized, the next step is selecting the appropriate materials for the DIP switch. The choice of materials depends on factors such as the switch's intended application, environmental conditions, and cost considerations. Common materials used for DIP switches include thermoplastics for the housing, copper alloy for the terminals, and gold or silver plating for the contacts. The selection of high-quality materials is crucial to ensure the switch's durability, electrical conductivity, and resistance to environmental factors such as temperature, humidity, and chemical exposure.3. Manufacturing Process (400 words)

The manufacturing process of DIP switches involves several key steps, including injection molding, metal stamping, contact assembly, and soldering. These steps are carried out in a controlled environment to maintain the quality and consistency of the switches.a. Injection Molding: The housing of the DIP switch is typically manufactured using injection molding. This process involves injecting molten thermoplastic material into a mold cavity, allowing it to cool and solidify into the desired shape. Injection molding offers high production efficiency, precise dimensional control, and the ability to create complex geometries.b. Metal Stamping: Metal stamping is employed to produce the switch terminals. A metal strip is fed into a stamping press, where a die cuts and forms the terminals into the required shape. This process ensures consistent terminal dimensions and accurate alignment for proper contact with the switch contacts.c. Contact Assembly: The switch contacts, usually made of copper alloy, are assembled onto the terminals. This can be done manually or using automated machinery, depending on the production volume. The contacts are carefully aligned and secured to ensure reliable electrical connections.d. Soldering: Soldering is a critical step in DIP switch production, as it ensures the electrical continuity between the contacts and terminals. The switch assembly is passed through a wave soldering machine, where it is exposed to a molten solder bath. The solder adheres to the contacts and terminals, creating a strong and reliable bond.4. Testing and Quality Control (300 words)

To ensure the functionality and reliability of DIP switches, rigorous testing and quality control measures are implemented throughout the production process. Various tests, including electrical, mechanical, and environmental tests, are conducted to verify the switch's performance under different conditions.a. Electrical Testing: Electrical tests are performed to verify the switch's electrical characteristics, such as contact resistance, insulation resistance, and actuation force. Specialized testing equipment is used to measure these parameters and ensure they meet the specified requirements.b. Mechanical Testing: Mechanical tests assess the switch's durability and actuation force. These tests involve repeatedly actuating the switch to simulate real-world usage and ensure its reliability over an extended period. Mechanical testing also includes assessing the switch's resistance to vibration, shock, and physical stress.c. Environmental Testing: Environmental tests evaluate the switch's performance under various environmental conditions, such as temperature extremes, humidity, and exposure to chemicals. These tests help determine the switch's resistance to factors that may affect its functionality and lifespan.5. Packaging and Distribution (200 words)

Once the DIP switches have passed all quality control tests, they are ready for packaging and distribution. The switches are carefully packaged to protect them from physical damage during transportation and storage. Packaging options include tape and reel packaging for automated assembly, tube packaging for manual assembly, or tray packaging for larger switches.Conclusion (100 words)

The mainstream DIP switch production process involves several crucial stages, from design and material selection to manufacturing, testing, and packaging. Each step plays a vital role in ensuring the quality, functionality, and reliability of these electronic components. By understanding the intricacies of DIP switch production, manufacturers can optimize their processes, adhere to industry standards, and deliver high-quality products to meet the ever-growing demands of the electronics industry.

Form: :

2024-01-17 14:08:04

0

Title: The Advantages of Limit Switch Products: Enhancing Safety and EfficiencyIntroduction (100 words)

Limit switch products are essential components in various industries, providing a reliable means of controlling and monitoring machinery and equipment. These devices offer numerous advantages that contribute to enhanced safety, increased efficiency, and improved productivity. In this article, we will explore the key benefits of limit switch products, highlighting their importance in industrial applications.1. Safety Enhancement (200 words)

One of the primary advantages of limit switch products is their ability to enhance safety in industrial environments. These devices are designed to detect and respond to specific conditions, ensuring that machinery operates within predetermined limits. By setting up limit switches at critical points, operators can prevent accidents, protect personnel, and minimize damage to equipment.Limit switches act as safety interlocks, shutting down machinery when certain conditions are met, such as excessive temperature, pressure, or vibration. This feature prevents catastrophic failures and reduces the risk of accidents caused by equipment malfunction or operator error. Additionally, limit switches can be used to control access to hazardous areas, ensuring that only authorized personnel can operate machinery in potentially dangerous zones.2. Equipment Protection (200 words)

Limit switch products play a crucial role in protecting machinery and equipment from damage. By monitoring specific parameters, such as position, speed, or torque, limit switches can prevent overloading, misalignment, or other conditions that may lead to equipment failure.For example, in conveyor systems, limit switches can be used to detect the presence of objects or to ensure that products are correctly positioned. By activating the switch when an object is detected or when the product reaches a specific location, the system can prevent jams, collisions, or other issues that could damage the conveyor or the products being transported.3. Process Optimization (200 words)

Limit switch products contribute to process optimization by providing accurate and reliable feedback on the status of machinery and equipment. By monitoring critical parameters, such as position, speed, or pressure, limit switches enable operators to fine-tune processes, improve efficiency, and reduce downtime.For instance, in automated assembly lines, limit switches can be used to verify the correct positioning of components, ensuring that each step of the process is completed accurately. By providing real-time feedback, limit switches allow operators to identify and address issues promptly, minimizing errors and improving overall product quality.4. Versatility and Adaptability (200 words)

Limit switch products are available in a wide range of configurations, making them highly versatile and adaptable to various industrial applications. They can be customized to meet specific requirements, such as different actuation methods, contact configurations, or environmental conditions.Whether it is a heavy-duty limit switch for harsh environments or a miniature limit switch for space-constrained applications, manufacturers offer a diverse selection of products to suit different needs. This versatility allows limit switches to be integrated seamlessly into existing systems or incorporated into new designs, ensuring compatibility and ease of installation.5. Cost-Effectiveness (200 words)

Limit switch products offer a cost-effective solution for industrial control and monitoring. Compared to other sensing devices, such as proximity sensors or photoelectric sensors, limit switches are generally more affordable, making them a preferred choice for many applications.Moreover, limit switches have a long operational life and require minimal maintenance, resulting in reduced downtime and lower overall costs. Their robust construction and resistance to harsh conditions ensure reliable performance, even in demanding environments, further contributing to cost savings.Conclusion (100 words)

Limit switch products provide numerous advantages that enhance safety, protect equipment, optimize processes, and offer versatility and cost-effectiveness. These devices play a crucial role in industrial applications, ensuring reliable control and monitoring of machinery and equipment. By incorporating limit switches into their systems, industries can achieve higher levels of safety, efficiency, and productivity.

Form: :

2024-01-17 06:24:05

0

Title: A Comprehensive Guide to Mainstream Models of Limit SwitchesIntroduction (100 words)

Limit switches are essential components in various industries, providing reliable and accurate detection of objects or limits of motion. With their ability to control machinery and ensure safety, limit switches have become indispensable in automation and control systems. In this article, we will explore the mainstream models of limit switches, discussing their features, applications, and advantages. By understanding the different types available, engineers and technicians can make informed decisions when selecting the most suitable limit switch for their specific needs.1. Basic Limit Switches (200 words)

Basic limit switches are the most common and widely used models. They consist of a mechanical actuator that triggers a switch when it comes into contact with an object or reaches a specific position. These switches are available in various configurations, including lever arm, roller plunger, and spring rod. Basic limit switches are known for their simplicity, durability, and cost-effectiveness. They find applications in industries such as automotive, packaging, and material handling.2. Safety Limit Switches (250 words)

Safety limit switches are designed to ensure the safety of personnel and equipment. They are equipped with additional features such as positive opening contacts, which guarantee the switch's contacts open even if they weld or stick together. Safety limit switches are often used in machinery where the detection of hazardous conditions, such as excessive temperature or pressure, is critical. These switches comply with international safety standards and are commonly found in industries like manufacturing, oil and gas, and pharmaceuticals.3. Proximity Limit Switches (250 words)

Proximity limit switches use non-contact sensing technology to detect the presence or absence of an object. They operate based on magnetic, inductive, or capacitive principles. Magnetic proximity switches use a magnet and a reed switch to detect the presence of ferrous objects. Inductive proximity switches generate an electromagnetic field and detect changes in the field caused by the presence of metallic objects. Capacitive proximity switches detect changes in capacitance when an object enters the sensing field. Proximity limit switches are widely used in automation and robotics applications due to their non-contact nature, high reliability, and long service life.4. Rotary Limit Switches (200 words)

Rotary limit switches are specifically designed to monitor the rotational movement of machinery or equipment. They consist of a rotating shaft with cams or lobes that actuate the switch contacts. These switches are commonly used in cranes, conveyors, and other heavy machinery to control the position and movement of loads. Rotary limit switches offer precise control over angular motion and are available in various configurations, including single and multi-turn models.5. Wireless Limit Switches (200 words)

Wireless limit switches provide the convenience of remote monitoring and control without the need for physical wiring. They use wireless communication technologies such as Bluetooth or Wi-Fi to transmit signals to a central control system. Wireless limit switches are particularly useful in applications where wiring is impractical or costly, such as in large-scale industrial facilities or hazardous environments. These switches offer flexibility, ease of installation, and reduced maintenance requirements.Conclusion (100 words)

Limit switches play a crucial role in automation and control systems, ensuring the safe and efficient operation of machinery. By understanding the mainstream models of limit switches, engineers and technicians can select the most appropriate switch for their specific application. Whether it's basic limit switches, safety limit switches, proximity limit switches, rotary limit switches, or wireless limit switches, each model offers unique features and advantages. By considering factors such as environmental conditions, required precision, and safety requirements, professionals can make informed decisions to optimize their systems' performance and reliability.

Form: :

2024-01-16 22:42:06

0

Title: Exploring the Popular Models of Fast: A Comprehensive GuideIntroduction:

Fast is a renowned brand that has gained significant popularity in the automotive industry. Known for its sleek designs, cutting-edge technology, and exceptional performance, Fast has become a favorite among car enthusiasts worldwide. In this article, we will delve into the popular models of Fast, highlighting their unique features, performance capabilities, and the reasons behind their success.1. Fast GT:

The Fast GT is a luxury sports car that combines elegance with high-performance capabilities. With its aerodynamic design, powerful engine, and advanced suspension system, the GT offers an exhilarating driving experience. Equipped with state-of-the-art technology, including a touchscreen infotainment system, advanced driver-assistance features, and a premium sound system, the GT ensures both comfort and convenience.2. Fast X1:

The Fast X1 is a compact SUV that has gained immense popularity due to its versatility and practicality. With its spacious interior, ample cargo space, and comfortable seating, the X1 is perfect for both urban commuting and adventurous road trips. The X1 boasts a range of safety features, such as lane departure warning, blind-spot monitoring, and adaptive cruise control, ensuring a secure and enjoyable driving experience.3. Fast ECO:

The Fast ECO is an electric vehicle that has revolutionized the automotive industry. With zero emissions and a long-range battery, the ECO offers an eco-friendly alternative without compromising on performance. The ECO's sleek design, regenerative braking system, and energy-efficient features make it an ideal choice for environmentally conscious drivers. Additionally, the ECO's fast-charging capabilities ensure minimal downtime during long journeys.4. Fast RS:

The Fast RS is a high-performance sports car that caters to adrenaline junkies and racing enthusiasts. With its powerful engine, precise handling, and aerodynamic design, the RS delivers an unmatched driving experience. The RS features advanced performance-enhancing technologies, such as launch control, adjustable suspension, and sport-tuned exhaust, allowing drivers to push the limits on both the track and the road.5. Fast LX:

The Fast LX is a luxury sedan that combines elegance, comfort, and performance. With its refined interior, plush seating, and cutting-edge technology, the LX offers a premium driving experience. The LX boasts a range of advanced safety features, including adaptive headlights, forward collision warning, and automatic emergency braking, ensuring the utmost safety for both the driver and passengers.Conclusion:

Fast has established itself as a prominent brand in the automotive industry, offering a diverse range of popular models that cater to various preferences and needs. From luxury sports cars to eco-friendly electric vehicles, Fast has successfully combined style, performance, and innovation. The GT, X1, ECO, RS, and LX models exemplify Fast's commitment to delivering exceptional driving experiences, making it a top choice for car enthusiasts worldwide. Whether you seek speed, comfort, or sustainability, Fast has a model that will undoubtedly exceed your expectations.

Form: :

2024-01-16 15:02:05

0

Title: The Evolution and Advantages of Touch Switches: A Comprehensive GuideIntroduction (100 words)

-----------------------

In today's technologically advanced world, touch switches have become an integral part of our daily lives. From smartphones and tablets to household appliances and automotive controls, touch switches have revolutionized the way we interact with electronic devices. This article aims to provide a comprehensive understanding of touch switches, their evolution, and the advantages they offer over traditional mechanical switches.1. Understanding Touch Switches (200 words)

------------------------------------------

Touch switches, also known as capacitive switches, are electronic devices that respond to the touch of a finger or a conductive object. Unlike mechanical switches that require physical pressure to make or break a connection, touch switches rely on the principles of capacitance to detect touch. When a conductive object, such as a finger, approaches the surface of a touch switch, it creates a change in the capacitance, triggering the switch to activate or deactivate.2. Evolution of Touch Switches (300 words)

-----------------------------------------

The concept of touch switches dates back to the early 1960s when they were first introduced as a replacement for mechanical switches in certain applications. However, it was not until the late 20th century that touch switches gained popularity due to advancements in technology and the miniaturization of electronic components. The introduction of touchscreens in smartphones and tablets further accelerated the development and adoption of touch switches.3. Types of Touch Switches (300 words)

--------------------------------------

There are several types of touch switches available today, each with its own unique characteristics and applications. Some common types include:a) Surface Capacitive Touch Switches: These switches use a transparent conductive coating on a glass or plastic surface. When a finger touches the surface, it disrupts the electrostatic field, triggering the switch.b) Projected Capacitive Touch Switches: Found in most modern smartphones and tablets, these switches use a grid of electrodes to detect touch. They offer multi-touch capabilities and are highly responsive.c) Resistive Touch Switches: These switches consist of two conductive layers separated by a thin insulating layer. When pressure is applied, the layers make contact, completing the circuit.d) Infrared Touch Switches: These switches use an array of infrared sensors to detect touch. When an object breaks the infrared beams, the switch is activated.4. Advantages of Touch Switches (400 words)

-------------------------------------------

Touch switches offer numerous advantages over traditional mechanical switches, making them increasingly popular in various industries. Some key advantages include:a) Durability: Touch switches have no moving parts, reducing the risk of wear and tear. This makes them highly durable and long-lasting, even in high-traffic environments.b) Hygiene: With touch switches, there is no need to physically press buttons, reducing the risk of germ transmission. This makes them ideal for applications in healthcare, food processing, and public spaces.c) Aesthetics: Touch switches offer sleek and modern designs, enhancing the overall aesthetics of electronic devices and appliances. They can be seamlessly integrated into various surfaces, providing a clean and clutter-free appearance.d) User-Friendly: Touch switches provide a more intuitive and user-friendly interface compared to mechanical switches. They offer features like gesture recognition, haptic feedback, and customizable layouts, enhancing the user experience.e) Versatility: Touch switches can be easily customized to meet specific requirements. They can be programmed to perform multiple functions, adapt to different languages, and incorporate various input methods.f) Energy Efficiency: Touch switches consume minimal power as they only activate when touched. This makes them energy-efficient and contributes to the overall sustainability of electronic devices.Conclusion (100 words)

-----------------------

Touch switches have come a long way since their inception, transforming the way we interact with electronic devices. With their durability, hygiene benefits, aesthetic appeal, and user-friendly interface, touch switches have become an integral part of modern technology. As technology continues to advance, touch switches are expected to evolve further, offering even more innovative features and applications.